Automotive

The automotive industry is constantly getting transformed by means of digitalization and globalization where, organizations need to retort and modernize to remain pertinent. Automotive manufacturers have an incredible opportunity to go beyond simply meeting industry standards. However, today’s automotive manufacturers experience a regulatory environment that reaches new heights on a regular basis as we march towards a new era of innovation in automotive where quality and compliance will be of utmost importance. Therefore, the focus on quality in automotive manufacturing is apparent, particularly among suppliers where, the need for them to demonstrate precise quality and compliance is very much an essential requirement for being considered as a supplier in the first place. Therefore a common set of regulations or standards that governs as to how a company makes and distributes its product or service to its customers safeguarding their brand name was in need for the industry. Therefore, ISO TS 16949 is a quality management assurance system that is primarily focused on the automobile industry that presents a global effort by stakeholders in the automobile industry and related sectors to promote the best and well developed management policies in the production of Automobiles in an effort to secure a safety and quality measure was devised. The IATF is a group of automotive manufacturers and their respective trade associations, formed to provide improved quality products to automotive customers worldwide.

The need for IATF 16949 Automotive QMS:

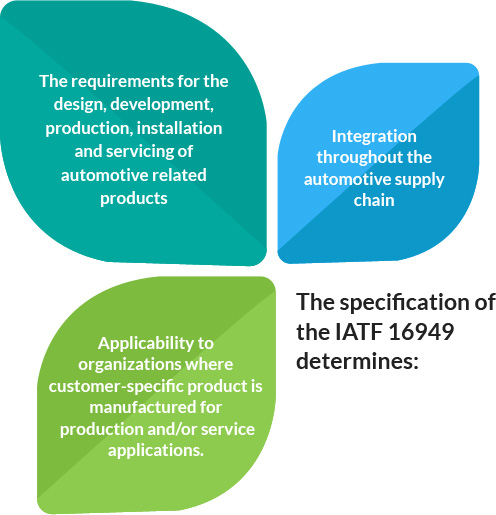

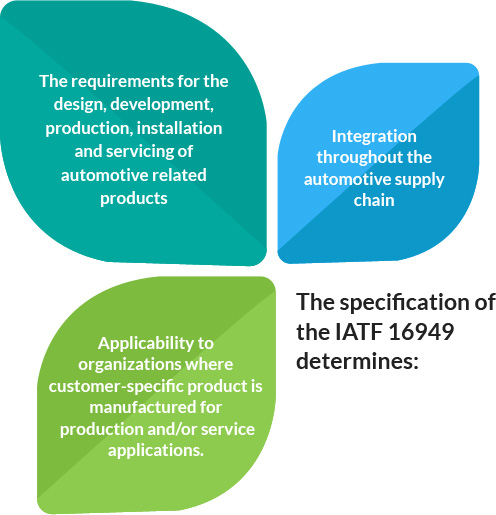

One of the automotive industry’s most widely used international standards for quality management, ISO/TS 16949, is evolving with the publication of a new global industry standard which is the International Automotive Task Force (IATF).IATF 16949:2016 brings together standards from across Europe and the U.S., outlining everything you need to know about achieving best practice when designing, developing, manufacturing, installing, or servicing automotive products recognized as the basis for any company, to create a system to ensure customer satisfaction and improvement, and as such, many companies demand this as the minimum requirement for an organization to be a supplier.

The primary focus of the IATF 16949 standard is the development of a Quality Management System that provides for continual improvement, emphasizing defect prevention and the reduction of variation and waste in the supply chain. The standard, combined with applicable Customer-Specific Requirements (CSR’s), define the QMS requirements for automotive production, service and/or accessory parts.

Implementing IATF 16949 ensures that customers receive consistent, good quality products and services, which in turn may bring many business benefits. IATF 16949 specifies requirements for a Quality Management System when an organization wants to:

- Demonstrate its ability to consistently provide products that meet customer and applicable statutory, regulatory and product safety requirements

- Enhance customer satisfaction through the effective application of the system

- Implement processes for improvement of the system

- Define overall context, who is affected and what they expect

- Clearly state objectives and identify new business opportunities

- Put customers first, making sure their needs are consistently met and enhance their satisfaction

- Have repeat customers, increase customer loyalty, add new clients and increase business

- Expand into new markets, as some sectors and clients require IATF 16949 before doing business

- Identify and address the risks associated with your organization

- Work in a more efficient way to increase productivity and efficiency, bringing internal costs down

- Become more socially responsible through the documentation and implementation of corporate responsibility polices

This new standard, which is based upon ISO 9001 standard, replaces the current ISO/TS 16949 and defines the requirements of a quality management system for organisations in the automotive industry.ISO TS 16949 reassures integrity and quality system control in all levels of production including supply of modern Automobiles, an initiative that has also been part of the International Automotive Task Force (IATF) policy frameworks.